In ancient Greece and Rome, the Dog Days were believed to be the time of drought, bad luck, and unrest, when dogs and men alike would be driven mad by the extreme heat. Today the phrase doesn't conjure up such imagery. It just means it is hotter than hell and dripping in humidity. Welcome to North Carolina in July !

I had a friend from Virginia come for a vacation to Topsail Beach a couple of weeks ago and invited him to take a spin on the Lykamobile. It was about 95 F (35 C) and the humidity was around 50% (which is drenching in 95 F heat). The Lykamobile did not like this at all. The inverter kept cutting out with its warning beep and the boiler only got up to about 180 PSI. Just enough to go a couple hundred feet. It was disappointing to all.

At first I thought it might be a low battery, not the case, the battery checked out. So I opened up the Silverline Inverter Manual we received and discovered that the inverter has a temperature safety cutoff of 65C (149F). That makes me think given the high daytime temperature possibly the inverter went into thermal cutoff. So the next day after everything had cooled off and in the morning with the outdoor temperature around 70F I take off the top panels and fire the Lykamobile up and with my temperature infared senser gun measured an astounding temperature on the Burner Tray of 663F (350C).

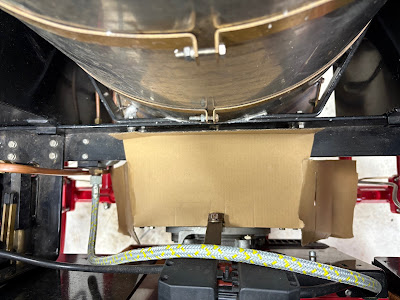

I measured where you can see the where the stainless steel burner tray has turned colors due to the extreme heat.So imagine with the top panel on, this area turns into a really hot oven, and in the Dog Days of Summer that inverter has little chance of keeping cool. There is a small fan that tries to suck in cooling air into the inverter, but I believe the enviroment in that back area would not be conducive to "cooling" the inverter.

To me that's an amazing drop in temperature!!!

.jpg)

.jpg)

.jpg)

.jpg)