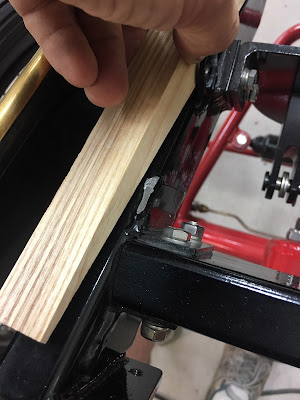

I discovered that the weldment below was causing the top board to lift up. A little grinding and some black touch-up paint solved that issue.

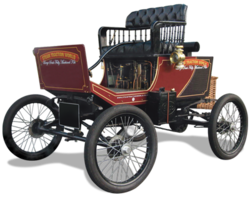

The 1899 Locomobile Steam Car Replica, known as the Lykamobile is a full scale live steam automobile manufactured in 24 kits. This kit is available from a company called "Steam Traction World" located in Daventry, United Kingdom. Each kit is to be manufactured and sent once a month for 24 months. However for cost considerations I have chosen to have my kits batched and dispatched in larger crates to the United States (Topsail Beach, NC).

Specifications:

• Length 7ft 2.6in • Height 5ft 3in • Width 4ft 7.1in • Weight 904 lbs.• Water Tank Capacity 12 Gallons • Fuel Tank Capacity 7.3 Gallons

Construction:

• CHASSIS Tubular steel fabrication, combination weld, bolted and silver solder.

• STEERING “Ackerman” design tiller steering.

• DIFFERENTIAL & DRIVE Spur gear differential similar to the original Locomobile, drive shaft and bearings.

• WHEELS & TYRES Single tube pneumatic, treaded.

• BREAKING SYSTEM Disc brake system.

• ENGINE 21/4" diameter, 3" stroke modified “Hackworth” valve gear.

• WATER FEED Twin mechanical pump.

• BURNER Fuelled by diesel.

• BOILER Multi Fire Tube, fully constructed and complete with necessary paperwork and inspected by notified body.

• BODYWORK & SEATS Wooden with steel frame, seating capacity of 2 persons, with turned decorative spindles with leather style upholstery.

• Gears: forward and reverse.

• Assemble with hand-tools only

• Step-by-step instructions

• Technical service and help-line backup

• Designed on ‘Solidworks’ CAD

• Manufactured on modern CNC machines for build accuracy and high quality

Saturday, June 20, 2020

Lyka Kit #23 Bodywork Panels Part 1

I discovered that the weldment below was causing the top board to lift up. A little grinding and some black touch-up paint solved that issue.

Friday, June 19, 2020

Lyka Kit #20 Burner Test Firing

Thursday, June 18, 2020

Lyka Kit #23 Bodywork Side Panels

Wednesday, June 17, 2020

Lyka Kit #20 Burner

Here the connector is all assembled with the connector covers installed.

Then drill out the new fitting to allow the 1/4 inch copper tube to be inserted and re-soldered.

Popular Posts

-

As probably like some of the fellow Lykamobile kit builders, I have been studying this kit for sometime now. A Lyka Series 1 builder (jjtjr ...

-

Kit # 15 arrived mid January 2019 while I was away on our annual buying trip to Atlanta for our two retail gift shops here on Topsail Island...

-

Kit # 2 was pretty straight forward. The assembly of the oil impregnated bushings into the steering tube went well. The assembly of the stub...

-

So September 19, 2015 I discovered the Lykamobile Steam Car through some Google search I did and promptly sent an email to Dean Rogers Direc...

-

Finally got all those pieces parts painted and cured. Took a little while longer due the winter temperatures. My garage is heated, but it st...

-

I have decided to paint my Lykamobile similar to an 1899 Locomobile that was recently auctioned off by Bonham's this past year. Below ar...

-

Below is an image of what I have found to be one of my most important tools -- a half round needle file. Also used extensively were a ...